The use of this compacting machine allows to reduce the volume powders up to 80%, allowing a considerable saving on transport costs and without any dispersion of the material.

IMPACT D-1 is built to obtain a maximum production of 1 m³ / h.

This compacting machine is

designed in a simple way to work for a long time without maintenance, therefore inexpensive.

What differentiates it from other com

petitors is:

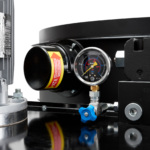

- the diameter of the compaction piston of 130mm (about 30% more than competitors)

- the capacity of the hydraulic unit (about 50 liters more)

- the predisposition to forced cooling

All this leads the machine to work slow while maintaining the initial capacity, and the oil not to heat up too much, the result: the gaskets and seals work for years before they have oil leaks.

On the side of the dust collection tank there is a porthol

e that allows you to check the level of the material (in the ECO model) or a probe that allows the IMPACT D-1 to work only in the presence of material to be compacted.

Features:

dimensions (mm): 1200 × 1000 × 1300 h (including the tank)

maximum dust reduction: 1:20

weight of the dry machine: 350 kg